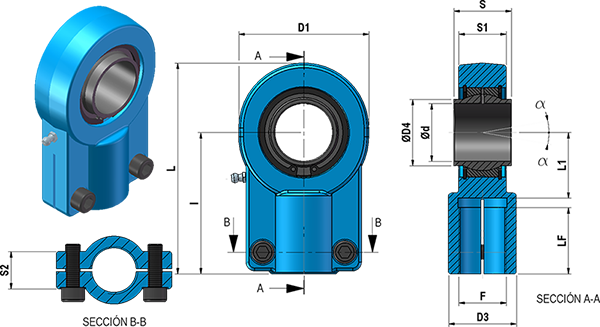

FIXATIONS – ROTULE DIN 24338 / ISO 6982

| Tolérance | Taux Charge Limite | Jeu | Angle | Pas vis | Couple Serrage | Poids | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| REF(*) | d | d | s | S | D4 | I | D1 | D2 | S1 | S2 | L | L1 | D3 | LF | F | Dynamique | Statique | Radial | d’oscilation | de pression | des vis | (kg) |

| mm | KN | mm | ||||||||||||||||||||

| TAPR 612 CE(1) | 12 | 0÷ +0.018 | 0÷ -0.18 | 12 | 15.5 | 38 | 32 | 32 | 11 | 15 | 54 | 14 | 16 | 17 | M12x1.25 | 10.8 | 24.5 | 0.023-0.068 | 4 | M5x16 | 6 | 0.11 |

| TAPR 616 CE | 16 | 0÷ +0.018 | 0÷ -0.18 | 16 | 20 | 44 | 40 | 40 | 13 | 15 | 64 | 20 | 21 | 19 | M14x1.5 | 17.6 | 36.5 | 0.030-0.082 | 4 | M6x14 | 10 | 0.20 |

| TAPR 620 CE | 20 | 0÷ +0.021 | 0÷ -0.21 | 20 | 25 | 52 | 47 | 47 | 17 | 19 | 75 | 22 | 25 | 23 | M16x1.5 | 30 | 48 | 0.030-0.082 | 4 | M8x20 | 25 | 0.35 |

| TAPR 625 CE | 25 | 0÷ +0.021 | 0÷ -0.21 | 25 | 30.5 | 65 | 58 | 54 | 22 | 19 | 96 | 27 | 30 | 29 | M20x1.5 | 48 | 78 | 0.037-0.100 | 4 | M8x20 | 25 | 0.62 |

| TAPR 632 CE | 32 | 0÷ +0.025 | 0÷ -0.25 | 32 | 38 | 80 | 71 | 66 | 28 | 22 | 118 | 32 | 38 | 37 | M27x2 | 67 | 114 | 0.037-0.100 | 4 | M10x25 | 49 | 1.15 |

| TAPR 640 CE | 40 | 0÷ +0.025 | 0÷ -0.25 | 40 | 46 | 97 | 90 | 80 | 33 | 26 | 146 | 41 | 47 | 46 | M33x2 | 100 | 204 | 0.043-0.120 | 4 | M10x30 | 49 | 2.18 |

| TAPR 650 CE | 50 | 0÷ +0.025 | 0÷ -0.25 | 50 | 57 | 120 | 109 | 96 | 41 | 32 | 179 | 50 | 58 | 57 | M42x2 | 156 | 310 | 0.043-0.120 | 4 | M12x35 | 86 | 3.96 |

| TAPR 663 CE | 63 | 0÷ +0.030 | 0÷ -0.30 | 63 | 71.5 | 140 | 136 | 114 | 53 | 38 | 211 | 62 | 70 | 64 | M48x2 | 255 | 430 | 0.055-0.142 | 4 | M16x40 | 210 | 6.80 |

| TAPR 670 CE(2) | 70 | 0÷ +0.030 | 0÷ -0.30 | 70 | 79 | 160 | 155 | 135 | 57 | 42 | 245 | 70 | 80 | 76 | M56x2 | 315 | 540 | 0.055-0.142 | 4 | M16x40 | 210 | 9.60 |

| TAPR 680 CE(2) | 80 | 0÷ +0.030 | 0÷ -0.30 | 80 | 91 | 180 | 170 | 148 | 67 | 48 | 270 | 78 | 90 | 86 | M64x3 | 400 | 695 | 0.055-0.142 | 4 | M20x50 | 410 | 13.00 |

| TAPR 690 CE(2) | 90 | 0÷ +0.035 | 0÷ -0.35 | 90 | 99 | 195 | 185 | 160 | 72 | 52 | 296 | 85 | 100 | 91 | M72x3 | 490 | 750 | 0.055-0.142 | 4 | M20x60 | 410 | 19.10 |

| TAPR 6100 CE(2) | 100 | 0÷ +0.035 | 0÷ -0.35 | 100 | 113 | 210 | 211 | 178 | 85 | 62 | 322 | 98 | 110 | 96 | M80x3 | 610 | 1060 | 0.065-0.165 | 4 | M24x60 | 710 | 25.00 |

| TAPR 6110 CE(2) | 110 | 0÷ +0.035 | 0÷ -0.35 | 110 | 124 | 235 | 235 | 190 | 88 | 62 | 364 | 105 | 125 | 106 | M90x3 | 655 | 1200 | 0.065-0.165 | 4 | M24x60 | 710 | 32.00 |

| TAPR 6125 CE(2) | 125 | 0÷ +0.040 | 0÷ -0.40 | 125 | 138 | 260 | 265 | 200 | 103 | 72 | 405 | 120 | 135 | 113 | M100x3 | 950 | 1430 | 0.065-0.165 | 4 | M24x70 | 710 | 46.00 |

| TAPR 6160 CE(2) | 160 | 0÷ +0.040 | 0÷ -0.40 | 160 | 177 | 310 | 326 | 250 | 130 | 82 | 488 | 150 | 165 | 126 | M125x4 | 1370 | 2200 | 0.065-0.192 | 4 | M24x80 | 710 | 82.50 |

| TAPR 6200 CE(2) | 200 | 0÷ +0.046 | 0÷ -0.46 | 200 | 221 | 390 | 418 | 320 | 162 | 102 | 620 | 195 | 215 | 161 | M160x4 | 2120 | 3650 | 0.065-0.192 | 4 | M30x100 | 1500 | 168.00 |

(1) Pas de graisseur

(2) Matériel: Fonte nodulaire (*) Si vous avez besoin de pas de à gauche, remplacer la lettre « R » par « L » du code de l’article EX. TAPL … CE. Disponibilité et prix sur demande. Il est possible de fournir les embouts à rotule sans entretien. Dans ce cas, les pièces n’ont pas de graisseur.

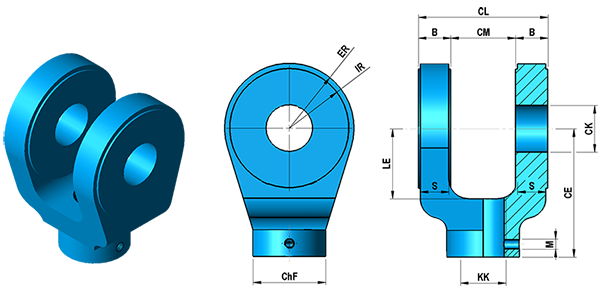

FIXATIONS – CHAPE FEMELLE SELON ISO 8133

| REF. | CM | CK(H9) | CE | CL | ChF | KK | LE | ER | B | IR | S | Filetage du Goujon |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CF 1310 | 12 | 10 | 32 | 24 | 19 | M10x1.25 | 13 | 12 | 6 | 10 | 5 | M 5×5 |

| CF 1310 | 12 | 10 | 32 | 24 | 19 | M10x1.25 | 13 | 12 | 6 | 10 | 5 | M 5×5 |

| CF 1312 | 16 | 12 | 36 | 32 | 21 | M12x1.25 | 19 | 17 | 8 | 15 | 7 | M 5×5 |

| CF 1314 | 20 | 14 | 38 | 40 | 21 | M14x1.5 | 19 | 17 | 10 | 15 | 8 | M 5×5 |

| CF 1316 | 30 | 20 | 54 | 60 | 32 | M16x1.5 | 32 | 29 | 15 | 26 | 13 | M 6×6 |

| CF 1316 | 30 | 20 | 54 | 60 | 32 | M16x1.5 | 32 | 29 | 15 | 26 | 13 | M 6×6 |

| CF 1320 | 30 | 20 | 60 | 60 | 32 | M20x1.5 | 32 | 29 | 15 | 26 | 13 | M 6×6 |

| CF 1327 | 40 | 28 | 75 | 80 | 40 | M27x2 | 39 | 34 | 20 | 30 | 17 | M 6×6 |

| CF 1333 | 50 | 36 | 99 | 100 | 56 | M33x2 | 54 | 50 | 25 | 46 | 22 | M 8×8 |

| CF 1342 | 60 | 45 | 113 | 120 | 56 | M42x2 | 57 | 53 | 30 | 49 | 27 | M 8×8 |

| CF 1348 | 70 | 56 | 126 | 140 | 75 | M48x2 | 63 | 59 | 35 | 38 | 31 | M 8×8 |

| CF 1364 | 80 | 70 | 168 | 160 | 95 | M64x3 | 83 | 78 | 40 | 45 | 37 | M 12×12 |

| CF 1380 | 80 | 70 | 168 | 160 | 95 | M80x3 | 83 | 78 | 40 | 74 | 37 | M 12×12 |

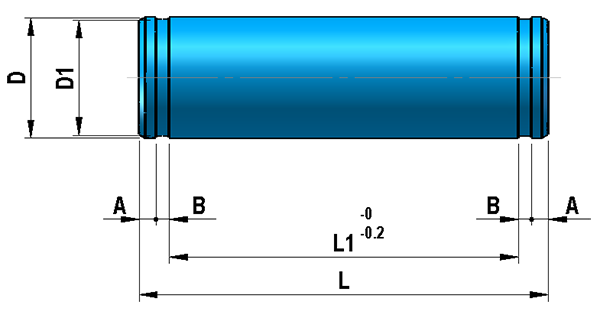

Clavis pour chape femelle ISO 8133

| REF. | D | L | D1 | L1 | A | B | Utilisé pour chape |

|---|---|---|---|---|---|---|---|

| PCF 1910 | 10 | 34 | 9.6 | 29 | 1.40 | 1.10 | CF 1310 |

| PCF 1911 | 12 | 43 | 11.5 | 37 | 1.90 | 1.10 | CF 1312 |

| PCF 1912 | 14 | 51 | 13.4 | 45 | 1.90 | 1.10 | CF 1314 |

| PCF 1913 | 20 | 73 | 19.0 | 66 | 2.20 | 1.30 | CF 1316 |

| PCF 1914 | 20 | 73 | 19.0 | 66 | 2.20 | 1.30 | CF 1320 |

| PCF 1915 | 28 | 95 | 26.6 | 87 | 2.40 | 1.60 | CF 1327 |

| PCF 1916 | 36 | 117 | 34.0 | 107 | 3.15 | 1.85 | CF 1333 |

| PCF 1917 | 45 | 139 | 42.5 | 129 | 3.15 | 1.88 | CF 1342 |

| PCF 1918 | 56 | 161 | 53.0 | 149 | 3.80 | 2.17 | CF 1348 |

| PCF 1919 | 70 | 181 | 67.0 | 169 | 3.35 | 2.65 | CF 1364 |

| PCF 1920 | 70 | 181 | 67.0 | 169 | 3.35 | 2.65 | CF 1380 |