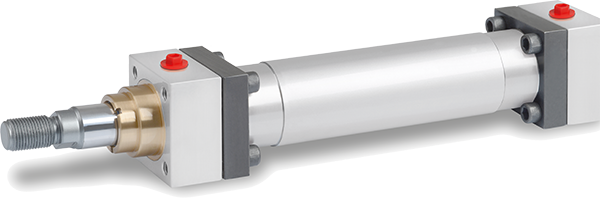

Tie Rods Hydraulic Cylinder

Tie rods hydraulic cylinder, in compliance with the ISO 6020/2 standard, also available with magnetic sensors.

All standard ISO mountings are available, in different seals configurations.

SPECIFICATIONS

| Standard Cylinders | ISO 6020/2 – DIN 24554 tie rods |

| Bore | From 25 to 100 -CD- || From 25 to 200 -DK- |

| Pressure(bar) | Operating: 160; Max 210 |

| Max Stroke | 4000 |

| Stroke Tolerance | 0 + 2 mm ISO 8131 Standard0 + 2mm Standard ISO 8131 |

| Fluid | Hydraulic mineral oil / Phosphoric esters / HFC-fluid |

| Viscosity | 12 … 90 mm2/S |

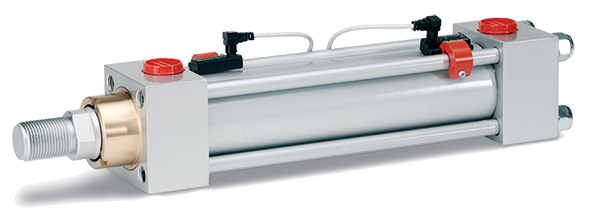

Hydraulic Cylinders with Counter Flanges

Hydraulic cylinders with counterflanges, in compliance with the ISO 6020/2 standard. They can be used with pressures up to 210 bar and they are suitable for long strokes. The cylinders are available in several different sealing configurations, depending on application conditions and desired performances.

SPECIFICATIONS

Standard Cylinders

ISO 6020/2 – DIN 24554 with counter flanges

Bore

From 50 to 100 -CD- || From 125 to 200 -DK-

Pressure(bar)

Operating: 160; Max 210

Max Stroke

4000

Stroke Tolerance

0 + 2 mm ISO 8131 Standard

Fluid

Hydraulic mineral oil / Phosphoric esters / HFC-fluid

ViscosityViscosité

12 … 90 mm2/S

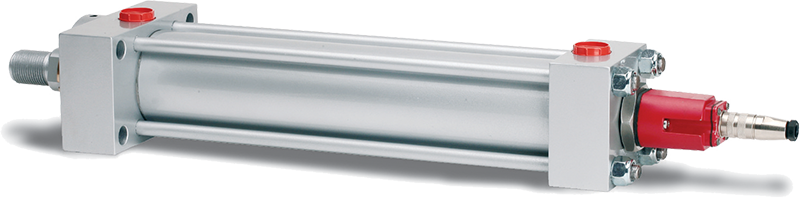

ISO 6020/2 Hydraulic Servocylinder

The ISO 6020/2 servocylinders are available both with tie rods (TD and TK versions) and with counter flanges (TH and TX version).

The servocylinders include an electronic transducer, which allows to obtain the absolute position of the rod. The type of transducer to be used depends on the performance you need.

The precision of positioning is determined by 2 elements: the resolution of the transducer and the drive system of the cylinder.

3 type of transducers are available:TEMPOSONIC: it allows high resolutions and different types of control; it supports all the stroke lengths necessary.POTENTIOMETRIC: the output signal is given from a cursor sliding on a piezoelectric. The maximum stroke allowed is 500 mm.INDUCTIVE: it emits a voltage or current signal generated by a separated electrical circuit. The maximum stroke allowed is 1000 mm.

SPECIFICATIONS

MV

MA

MS

PV

IV

IA

Transducer type

Temposomic

Temposomic

Temposomic

Potenciometric

InductiveInductif

Inductive

Supply Voltage

24V DC

24V DC

24V DC

Max 60V

24V DC

24V DC

Output

0-10V

4-20mA

SSI

0-10V

4-20mA

Resolution

Endless

Endless

Endless

Endless

Endless

Linearity

<±0.02% F.S. (min ± 50 μm)

<±0.02% F.S. (min ± 50 μm)

<±0.01% F.S. (min ± 50 μm)

±0.1% F.S.

±0.2% F.S.

±0.2% F.S.

Repeatability

<±0.001% F.S. (min ± 2.5 μm)

<±0.001% F.S. (min ± 2.5 μm)

<±0.001% F.S. (min ± 2.5 μm)

Hysteresis

<4 μm

<4 μm

<4 μm

Absorption

100 mA

100 mA

100 mA

Max Speed

2 m/s

2 m/s

2 m/s

1 m/s

2 m/s

2 m/s

Temperature

-20 +70 °C

-20 +70 °C

-20 +70 °C

-20 +70 °C

-20 +70 °C

-20 +70 °C

Max Stroke

2500

2500

2500

500

1000

1000

The servocylinders can be equipped with ISO interface plates, which allow to mount directly on the cylinder the following elements:

– Solenoid valves ON/OFF

– Proportional solenoid valves

– Servovalves

ISO 6020/2 Compact Hydraulic Cylinder

Light Compact Hydraulic Cylinder (Short Stroke)

[/fusion_builder_column]

Double acting hydraulic cylinders, realized in high resistance aluminum with wearresistant coating. Suitable for industrial automation applications, not in heavy duty conditions, when a light, compact and highly modular construction is required.

Designed also for use with integrated magnetic sensors to control the piston position.

SPECIFICATIONS

Bore

from 25 to 63

from 80 to 100

Max Pressure

160

100

Stroke

20,50, 80, 100

Heavy Duty Compact Hydraulic Cylinders (Short Stroke)

Double acting hydraulic cylinders, realized in steel for heavy duty uses. Suitable for industrial automation applications, when a strong, compact and highly modular construction is required.

Available also with anti-rotation device and mechanic stroke limiters to control the final rod positions.

SPECIFICATIONS

Bore

from 25 to 100

Operating Pressure

250. Max 320.

Stroke

20,50, 80, 100

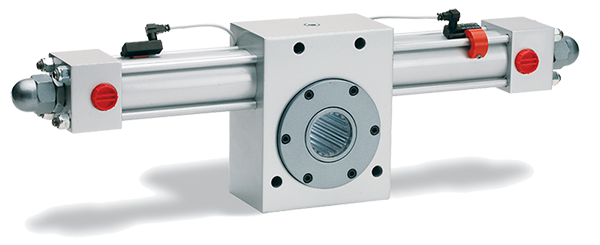

Rotary Actuator

Rotary actuators generate a torque through a cogwheel and a rack moved by a hydraulic cylinder.

This solution simplifies the kinematic and the maintenance required during its life cycle.

Rotary actuators have an adjustable cushioning, which can generate a cushioning torque comparable to the maximum torque of the cylinder. The stroke end adjuster allows phasing the system with a regulation range of +/-5°. They are also available in a version with magnetic piston for applications with magnetic proximity switches along the stroke of the piston.